Stepping into the world of biofabric technology feels a bit like peering into the future, doesn’t it? I remember thinking just a few years ago that creating textiles or even human tissues from living organisms was pure science fiction.

Yet, here we are, witnessing a revolution unfold before our very eyes. This isn’t just about ‘green’ materials; it’s about fundamentally reshaping how we make things, from sustainable clothing that literally grows, to life-saving medical implants that integrate seamlessly with our bodies.

The underlying science is complex, a brilliant dance between biology and engineering, and it’s set to disrupt so many industries in ways we’re only beginning to grasp.

I’ve personally seen how much buzz biofabric has generated, especially in circles pushing for true sustainability, moving beyond mere recycling to entirely regenerative cycles.

It truly struck me how this field is tackling massive issues like textile waste and the critical shortage of donor organs head-on. Looking ahead, I firmly believe we’re just scratching the surface.

We’ll see biofabricated organs becoming a norm, not just a distant dream, and fashion lines featuring materials grown in labs, tailored to order, completely changing our relationship with consumption.

It’s a challenging journey, sure, with hurdles like scalability and cost, but the sheer potential feels unstoppable. Let’s get into the specifics.

The Groundbreaking Science Unveiling Biofabrication’s Potential

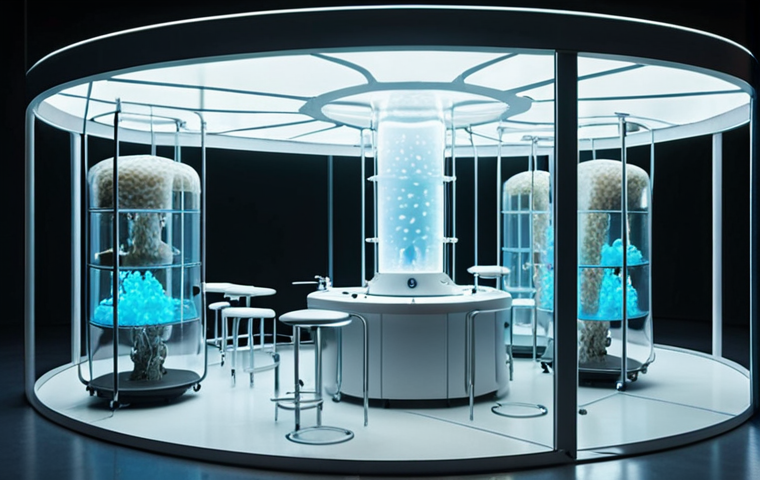

Stepping into the nitty-gritty of biofabrication, it really hit me how ingeniously nature’s blueprints are being leveraged. It’s not just about growing stuff; it’s about a meticulously choreographed dance between living cells and sophisticated engineering. When I first dove into the core principles, I was genuinely astonished at the sheer complexity and elegance. We’re talking about using cells, whether they’re from plants, fungi, bacteria, or even human tissues, as miniature factories. These tiny biological powerhouses are coaxed into producing specific molecules, like cellulose, collagen, or silk proteins, which then form the building blocks of materials. Think about it: instead of extracting resources, we’re cultivating them. It feels like we’re finally catching up to what nature has been doing for billions of years, just with a scientific twist. This process is deeply rooted in fields like synthetic biology, genetic engineering, and material science, all working in concert to create something truly unprecedented.

1. Cellular Agriculture: Growing Beyond the Farm

When I think of cellular agriculture, my mind immediately jumps to the revolutionary idea of “growing” materials without the need for vast swathes of land or traditional farming. It’s a concept that really resonated with me, especially considering the enormous environmental footprint of conventional manufacturing. Imagine a future where your leather jacket isn’t from an animal, but grown in a lab from a few initial cells, or your silk scarf didn’t require silkworms, but was spun by engineered microbes. This isn’t science fiction anymore; companies are already making significant strides in producing bio-identical materials like ‘spider silk’ without the spiders, or cultivating leather using animal cells. The precision is incredible; we can control the exact properties of the material at a molecular level, tailoring its strength, elasticity, and even breathability. This approach fundamentally changes the supply chain, moving from a resource-extractive model to a bio-regenerative one, offering a compelling solution to many of the planet’s pressing ecological issues that, frankly, keep me up at night.

2. Bio-printing and Tissue Engineering: Crafting Life Layer by Layer

The first time I saw a demonstration of 3D bioprinting, it honestly felt like watching a magic trick. The ability to deposit living cells layer by layer to construct complex 3D tissues and organs is nothing short of breathtaking. My initial thought was, “This is it, the future of medicine!” This isn’t just about making simple structures; we’re talking about intricate geometries, complete with vascular networks, designed to mimic native human tissues. Researchers are developing everything from skin grafts that seamlessly integrate with burn victims to miniature organs for drug testing, drastically reducing the need for animal trials. The precision offered by bio-printing allows for the exact placement of different cell types and biomaterials, creating scaffolds that guide tissue development. It’s a meticulous process, but the potential to address the critical shortage of donor organs and provide personalized medicine is just immense. It truly represents a paradigm shift in how we approach regenerative therapies, making previously unimaginable treatments seem within reach.

Revolutionizing the Fashion and Textile Industry Through Sustainable Innovation

The fashion industry, as we all know, has a notoriously heavy environmental burden, and honestly, it’s something that always bothered me. From water consumption to chemical dyes and immense waste, it’s a constant struggle to balance style with sustainability. This is precisely where biofabric technology steps in as a genuine game-changer. I’ve been following several startups in this space, and what they’re achieving is nothing short of revolutionary. Imagine textiles that literally grow, using far less water and energy than conventional cotton or synthetic fibers. We’re talking about materials like mushroom-based “leather” (mycelium) that biodegrade naturally, or fabrics engineered from bacterial cellulose that offer superior strength and unique textures. It’s not just about being “green”; it’s about fundamentally rethinking the entire lifecycle of a garment, from its origin to its eventual return to the earth. This shift towards regenerative materials offers a truly circular economy model, something I’ve passionately advocated for, moving beyond simply recycling existing waste to creating products that are inherently sustainable from the cellular level upwards.

1. Mycelium: The Mushroom-Powered Material Revolution

When I first heard about using mycelium – the root structure of mushrooms – to create leather, I admit I was skeptical. But then I saw and felt the samples, and my jaw dropped. It’s genuinely soft, durable, and has that tactile richness you’d expect from premium leather, all while being completely animal-free and compostable. This technology addresses so many of the ethical and environmental concerns I’ve had with traditional leather production. Brands are already integrating mycelium into their collections, from high-end fashion houses to everyday accessories, proving its commercial viability. The process is remarkably efficient; the mycelium grows quickly on agricultural waste, requiring minimal resources and producing virtually no waste. It truly feels like a breakthrough, offering a luxurious and performance-driven alternative that doesn’t compromise on our values or the planet’s well-being. This is the kind of innovation that makes me genuinely optimistic about the future of sustainable fashion.

2. Bio-Engineered Fibers: Performance Meets Planet

Beyond mycelium, the world of bio-engineered fibers is equally thrilling. Think about fabrics made from algae, or even genetically engineered microbes that excrete silk proteins. What really excites me about these innovations is their ability to combine high performance with environmental responsibility. We’re not just creating “eco-friendly” alternatives that might compromise on quality; we’re developing materials that can outperform their traditional counterparts in specific ways. For example, some bio-fabricated silks offer enhanced strength-to-weight ratios or unique moisture-wicking properties, making them ideal for performance wear. This means athletes, for instance, can wear gear that’s not only better for the environment but also enhances their performance. This duality – ethical production coupled with superior functionality – is what will truly drive widespread adoption and, from my vantage point, transform our closets in the years to come. It’s a win-win that feels incredibly overdue.

The Medical Marvels of Biofabricated Organs and Tissues: A New Frontier

In the realm of medicine, biofabrication isn’t just an improvement; it’s a radical rethinking of how we approach organ transplantation, regenerative therapies, and drug development. Having heard countless stories of patients waiting for life-saving organ transplants, often for years, the promise of creating custom, on-demand organs feels like a true miracle on the horizon. The science here is incredibly intricate, involving not just growing cells, but guiding them to form complex, functional structures that can seamlessly integrate with the human body. It truly blows my mind to think that a patient’s own cells could be used to print a replacement organ, eliminating the risk of rejection, which is a massive hurdle in current transplant medicine. This isn’t a distant dream; researchers are already making significant strides with simpler tissues, paving the way for more complex organs. It’s a journey that will undoubtedly face significant ethical and regulatory challenges, but the potential to save and drastically improve lives is so profound that the efforts feel overwhelmingly justified.

1. Custom Organ Transplants: Tailored to Perfection

The idea of a custom-made organ, perfectly matched to a patient’s immune system, is the holy grail of regenerative medicine. When I first learned about how biofabrication could achieve this, I immediately thought of the incredible relief it would bring to families waiting for transplants. By using a patient’s own cells, or even universal donor cells that are engineered to be non-immunogenic, the risk of organ rejection—a constant worry and a major reason for transplant failure—is virtually eliminated. This isn’t just about replacing a damaged liver or kidney; it’s about creating a living, breathing organ that functions precisely as needed, without the lifelong need for powerful immunosuppressant drugs that often come with severe side effects. The ability to create personalized tissues for damaged hearts, corneas, or even portions of a liver on demand would not only alleviate the global organ shortage but also fundamentally change the quality of life for millions of people worldwide. It’s an intensely personal and profoundly hopeful prospect.

2. Advanced Drug Testing and Disease Modeling: Precision Medicine Accelerated

Beyond full organ replacement, biofabricated tissues are also revolutionizing drug discovery and disease modeling. This aspect personally fascinates me because it has the potential to dramatically accelerate medical breakthroughs. Instead of relying solely on animal testing, which doesn’t always translate perfectly to human physiology, or two-dimensional cell cultures, scientists can now create “organs-on-a-chip” or more complex 3D human tissue models. These bio-printed models – miniature kidneys, livers, or even brains – behave much more like real human organs, providing a far more accurate platform for testing new drugs, understanding disease progression, and studying drug metabolism. From my perspective, this means drugs can be developed faster, with fewer failures, and with greater safety, ultimately benefiting patients more quickly. It also allows for highly personalized drug screening, testing how an individual’s specific tissues would react to different treatments, pushing us further into an era of truly personalized medicine, which I believe is where the future of healthcare undeniably lies.

Addressing Environmental Challenges with Biofabric: A Sustainable Future

For anyone who cares deeply about our planet, the environmental promise of biofabric technology is incredibly compelling. I’ve personally felt the frustration of seeing headlines about overflowing landfills, plastic pollution choking our oceans, and industrial processes draining our precious resources. Biofabric offers a tangible pathway out of this mess. It represents a fundamental shift from a linear “take-make-dispose” economy to a circular, regenerative one. We’re talking about processes that inherently reduce waste, minimize water and energy consumption, and often utilize renewable feedstocks. My hope is that as this technology scales, it won’t just be a niche solution but a mainstream approach to manufacturing that drastically reduces humanity’s ecological footprint. It’s not just about creating new materials; it’s about redefining our entire relationship with production and consumption, building a future where industry and nature can coexist in harmony, something I genuinely believe is achievable through these kinds of innovations.

1. Reduced Resource Consumption: Less Land, Less Water, Less Energy

One of the most striking advantages of biofabrication, from an environmental standpoint, is its incredible efficiency in resource utilization. Traditional manufacturing often demands vast tracts of land, enormous quantities of water, and significant energy for cultivation, processing, and transportation. Think about cotton farms needing extensive irrigation, or livestock farming requiring huge land areas for grazing and feed production. Biofabrication, by contrast, typically occurs in controlled bioreactor environments. This means a drastically smaller land footprint, precise control over water usage (often with closed-loop systems), and significantly lower energy demands compared to conventional methods. My personal observation has been that this efficiency isn’t just theoretical; it’s being demonstrated in pilot projects and small-scale commercial operations, proving that we can produce high-quality materials with a fraction of the environmental cost. It’s a powerful argument for accelerating the adoption of these technologies on a global scale.

2. Biodegradability and Circularity: Closing the Loop on Waste

The concept of “closing the loop” on waste is something I’ve championed for years, and biofabrication is perhaps the most elegant solution I’ve seen to date. Many biofabricated materials are designed from the ground up to be inherently biodegradable, returning their components safely to the earth at the end of their life cycle. This stands in stark contrast to synthetic materials like plastics, which persist for centuries. Imagine a future where your clothes, packaging, and even some medical devices simply decompose, enriching the soil rather than polluting it. This natural decomposition avoids the massive problem of textile waste and plastic accumulation. Furthermore, the inputs for biofabrication often come from renewable sources or even waste streams themselves (like agricultural byproducts), further enhancing their circularity. It truly embodies the ideal of a regenerative system, one where we mimic nature’s own cycles of growth, use, and decomposition, and that, for me, is the ultimate vision for a sustainable future.

Overcoming Hurdles: Scalability and Cost Implications in Biofabrication

While the vision for biofabrication is incredibly bright, I’d be remiss not to acknowledge the significant hurdles that need to be overcome, particularly in terms of scalability and cost. This is where the rubber meets the road, transforming groundbreaking lab research into commercially viable products. From my perspective, this is often the most challenging phase for any revolutionary technology. The processes involved in growing cells and engineered materials are complex and require highly specialized equipment and expertise. Scaling up from a petri dish to industrial-sized bioreactors while maintaining consistency and quality is no small feat. The initial investment in research, development, and infrastructure is substantial, which naturally translates to higher production costs compared to established, mass-produced materials. However, what gives me hope is the rapid pace of innovation in bioprocessing and the increasing investment from both private and public sectors, signaling a strong belief in its long-term potential. We’ve seen similar trajectories with other emerging technologies, where initial high costs eventually decrease with economies of scale and technological advancements.

1. The Challenge of Industrial Production and Infrastructure

The transition from a laboratory setting to industrial-scale production is a gargantuan task for biofabrication. I’ve often thought about the sheer complexity involved in moving from small-batch cultivation to systems capable of producing tons of material consistently. This requires designing and building specialized bioreactors, optimizing nutrient feeds for cell growth, ensuring sterile environments to prevent contamination, and developing efficient downstream processing methods to extract and purify the desired materials. The infrastructure needed is immense and represents a significant capital expenditure. We’re talking about factories that look very different from traditional textile mills or chemical plants. Furthermore, finding and training a workforce with the unique blend of biological and engineering expertise required for these operations is another considerable challenge. It’s a heavy lift, but with every successful pilot plant and every new investment, the pathway to broader adoption becomes clearer, slowly but surely overcoming what initially feels like an insurmountable barrier.

2. Driving Down Costs: The Path to Market Competitiveness

Currently, many biofabricated materials are priced at a premium, making them primarily accessible to niche luxury markets or specialized medical applications. This is a common phenomenon for nascent technologies, and it’s a concern I often hear when discussing mainstream adoption. The high costs stem from the intensive R&D, specialized equipment, and relatively low production volumes. However, the trajectory for these technologies typically involves a significant cost reduction curve as processes become more efficient, raw material sourcing optimizes, and production scales up. Think about the initial cost of solar panels or electric vehicles, which have plummeted over time. For biofabrication, this means innovations in cell line optimization, cheaper nutrient media, more efficient bioreactor designs, and improved purification techniques. My belief is that as investment pours in and technological breakthroughs continue, we will see these materials become competitive with, and eventually even cheaper than, some traditional materials, especially when you factor in their environmental benefits. It’s a race against time, but one that feels increasingly winnable.

The Ethical Landscape and Regulatory Frameworks for Biofabrication

Whenever a truly disruptive technology emerges, especially one that interacts so intimately with living systems, it’s absolutely crucial to have robust ethical discussions and clear regulatory frameworks in place. Biofabrication is no exception. I’ve been involved in conversations where the questions range from the philosophical (“What does it mean to ‘grow’ a material or an organ?”) to the practical (“How do we ensure these products are safe and transparently produced?”). It’s a complex tightrope walk, balancing innovation with responsibility. We need to ensure that as we push the boundaries of what’s possible, we do so in a way that aligns with societal values, respects biological integrity, and prioritizes human and environmental well-being. This requires ongoing dialogue between scientists, ethicists, policymakers, and the public, which, from my experience, is often slow but absolutely necessary to build trust and ensure the technology’s responsible deployment. Without this careful consideration, even the most promising advancements can falter.

1. Ethical Considerations: Defining “Natural” and “Living” Materials

The ethical implications of biofabrication are deep and multifaceted. Questions inevitably arise: Is a leather grown from cells truly “vegan”? What are the moral implications of growing human tissues for non-medical purposes, even if it’s just for fashion? These aren’t simple yes/no answers, and I’ve found that people have vastly different perspectives. For me, it comes down to transparency and intent. If a material is grown from cells, but no animal was harmed in the process and the cells are not sentient, it certainly feels ethically superior to traditional animal products. However, clear communication with consumers is paramount. Furthermore, as we delve into creating complex biological structures, questions about sentience and the sanctity of life might arise, especially in the far future of advanced organ fabrication. Navigating these ethical waters requires open discourse, careful consideration of societal norms, and a commitment to transparency, which I believe is essential for public acceptance and the long-term success of the technology.

2. Navigating Regulatory Pathways and Public Acceptance

For biofabricated products to reach the mass market, they need to navigate a labyrinth of regulatory hurdles, and this is an area where I see both challenges and opportunities. For medical applications, agencies like the FDA in the U.S. or the EMA in Europe will require rigorous testing for safety, efficacy, and long-term integration, which is a lengthy and costly process. For consumer products like bio-fabricated textiles, while direct medical regulation might not apply, there will still be a need for clear labeling, environmental impact assessments, and perhaps new certification standards. My personal take is that proactive engagement with regulatory bodies from the outset is crucial. Companies that demonstrate transparency and a commitment to safety and sustainability will build public trust more effectively. Education is also key; the more people understand how these materials are made and the benefits they offer, the more likely they are to accept and embrace them. It’s a journey that demands patience and persistent advocacy, but the potential rewards for society are immeasurable.

| Aspect | Traditional Manufacturing | Biofabrication |

|---|---|---|

| Resource Origin | Extractive (e.g., petroleum, animal farming, mining) | Cultivated (e.g., cells, microbes, plants) |

| Environmental Footprint | High (land use, water, energy, pollution, waste) | Significantly lower (reduced land/water, circularity, biodegradability) |

| Waste Profile | Persistent, often non-biodegradable waste | Often biodegradable, minimal or recyclable byproducts |

| Ethical Considerations | Animal welfare, labor practices, resource depletion | Defining “living” materials, genetic engineering, transparency |

| Customization Potential | Limited, based on raw material properties | High, precise control over material properties at cellular level |

| Scalability | Mature, established supply chains | Developing, currently higher cost at scale |

A Glimpse into Tomorrow: The Future of Biofabric Technology

Looking ahead, the future of biofabric technology feels less like a distant dream and more like an accelerating reality, and honestly, it sparks a deep sense of excitement in me. We’re on the cusp of an era where our relationship with materials and medicine will be fundamentally transformed. I envision a world where personalized medicine is the norm, with organs printed on demand, perfectly matched to each patient’s unique biological signature. Think about the profound impact on waiting lists, the elimination of rejection drugs, and the extension of healthier, more vibrant lives. In the realm of consumer goods, I foresee fashion houses regularly showcasing garments grown in labs, tailored not just to size but to specific performance needs or even emotional connection. Packaging will be designed to disappear harmlessly, returning to the earth, rather than accumulating in landfills. This isn’t just about incremental improvements; it’s about a paradigm shift that promises to solve some of humanity’s most pressing challenges, from climate change and resource scarcity to health crises. It’s a future that feels genuinely hopeful and sustainable, driven by ingenuity and a profound respect for life’s fundamental building blocks.

1. Hyper-Personalization: From Organs to Outfits

One of the most captivating aspects of biofabrication’s future, for me, is the potential for hyper-personalization. Imagine a doctor scanning your unique biology and a bio-printer then creating a heart valve that’s an exact match, not just in size but in cellular composition, perfectly integrating with your body without a hitch. This level of precision is currently unfathomable with traditional methods. But it’s not just in medicine. Picture a future where your running shoes are bio-printed with a sole perfectly customized to your gait, foot pressure points, and even the terrain you run on. Or clothing that adapts to your body temperature, changes color based on your mood, or even self-repairs. This isn’t just about aesthetics; it’s about optimizing performance, comfort, and functionality on an individual level. It transcends mass production, offering products that are uniquely tailored to each person’s needs and desires. It’s a truly exhilarating prospect that reshapes how we think about product design and ownership, moving towards items that are truly ‘yours’ in every sense.

2. Integration with AI and Robotics: The Smart Bio-Factory

The synergy between biofabrication, artificial intelligence, and robotics is what truly excites me about the long-term future of this field. I can visualize fully automated bio-factories, where AI algorithms meticulously design new materials or organ scaffolds, optimizing for specific properties or functionalities. Robotic arms would then precisely handle delicate biological cultures, monitor growth conditions, and assemble complex bio-structures with unparalleled accuracy and speed. AI could also analyze vast datasets of biological responses, accelerating the discovery of new cell lines or growth protocols, drastically cutting down development time. This integration promises to address the current challenges of scalability and cost, making biofabricated products more accessible and affordable. Furthermore, AI could revolutionize quality control, identifying anomalies in growth or structural integrity with superhuman precision. This isn’t just about manufacturing; it’s about creating an intelligent, self-optimizing biological production system that can continuously innovate and improve, propelling us into an era of unprecedented efficiency and sustainable creation. It’s a vision that truly feels like the next industrial revolution, powered by biology and intelligence.

Concluding Thoughts

As I reflect on the incredible journey we’ve just taken through the world of biofabrication, one thing becomes abundantly clear: this isn’t just another scientific advancement; it’s a profound shift in how we interact with the material world and our own bodies.

From revolutionizing fashion and textiles to offering life-saving medical breakthroughs and presenting truly sustainable solutions to environmental crises, biofabric technology is poised to redefine our future.

While the path ahead is filled with challenges, particularly around scalability and cost, the sheer ingenuity and dedication of researchers and innovators in this space give me immense hope.

It’s a testament to human creativity, pushing the boundaries of what’s possible, and I truly believe we’re just scratching the surface of its transformative potential.

Useful Information to Know

1. Biofabrication encompasses a wide range of technologies, including cellular agriculture (growing materials like leather and silk from cells) and 3D bioprinting (layering living cells to create tissues and organs).

2. It aims to significantly reduce the environmental footprint of traditional manufacturing by minimizing land, water, and energy use, and by producing inherently biodegradable materials.

3. In medicine, biofabrication holds immense promise for personalized organ transplants, eliminating rejection risks, and creating more accurate human tissue models for drug testing.

4. While incredibly promising, current hurdles include high production costs and the challenge of scaling up from lab-based processes to industrial-level manufacturing.

5. Ethical discussions and regulatory frameworks are actively being developed to ensure responsible innovation, particularly concerning the definition of “natural” and “living” materials and their societal implications.

Key Takeaways

Biofabrication represents a paradigm shift, moving us towards a regenerative, bio-circular economy where materials are grown, not extracted. It’s a field brimming with potential to deliver personalized medicine, sustainable fashion, and innovative solutions to global challenges, fundamentally reshaping industries and our relationship with nature, all while fostering a more resilient and sustainable future.

Frequently Asked Questions (FAQ) 📖

Q: Okay, so it sounds incredible, but where are we really seeing biofabric technology making a tangible difference right now, beyond the lab prototypes?

A: That’s such a crucial question, isn’t it? Because it’s easy to get lost in the future vision. But honestly, I’ve seen some truly impressive breakthroughs already landing in the market.

Think about biomaterials for fashion – companies like Mylo and Bolt Threads have been creating lab-grown leather alternatives that look and feel just like the real deal, without the huge environmental footprint of traditional leather.

I even saw a designer friend showcasing a jacket made from one of these materials at a pop-up in Brooklyn last year, and you absolutely couldn’t tell it wasn’t cowhide.

It blew my mind! On the medical side, while full organ fabrication is still some way off for widespread use, we’re seeing biofabricated scaffolds used for tissue repair, even advanced wound dressings that help skin regenerate.

It’s not front-page news for everyone yet, but if you’re looking, it’s there, quietly revolutionizing things piece by piece.

Q: It sounds like a game-changer, but what are the biggest roadblocks to biofabric technology truly becoming mainstream, especially regarding cost and making enough of it?

A: Oh, that’s where the rubber meets the road, isn’t it? I’ve been in so many discussions where this exact point comes up. The biggest hurdles right now are definitely scalability and cost.

Imagine going from a small bioreactor in a lab to producing tons of material – that transition is incredibly complex and capital-intensive. It’s not like just scaling up a traditional factory; you’re dealing with living systems!

Plus, the R&D investment is massive, and specialized equipment isn’t cheap. For medical applications, the regulatory pathway – getting FDA approval for a biofabricated organ, for example – is a multi-year, multi-million dollar marathon.

It’s not just about the science; it’s about navigating an entirely new manufacturing paradigm and convincing regulators and consumers that these products are safe, reliable, and actually better.

It reminds me a bit of the early days of solar power – revolutionary potential, but steep upfront costs and a whole new infrastructure to build out before it became competitive.

Q: The environmental benefits are a huge part of biofabric’s appeal. How does it truly measure up against traditional materials or even existing recycling efforts in terms of sustainability?

A: This is where I get really passionate about biofabric, honestly. We’ve been talking about ‘sustainability’ for years, but often it’s just been about making things less bad.

Biofabric, to me, represents a fundamental shift towards truly regenerative cycles. Think about it: instead of relying on petroleum for synthetics, or immense land and water for cotton or livestock for leather, you’re growing materials in a controlled environment.

The potential to use far less water, energy, and land is staggering. And the best part? Many of these materials are designed to be biodegradable at the end of their life, returning to nature rather than clogging landfills for centuries.

It’s a massive step beyond simply recycling an existing product – it’s about re-imagining the entire lifecycle. While there are still energy inputs for the bioreactors, it’s a vastly more controlled and efficient process than industrial farming or chemical synthesis.

It’s not a silver bullet, no technology ever is, but it really feels like the closest we’ve come to a manufacturing approach that works with nature, not against it.

📚 References

Wikipedia Encyclopedia

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과